Market News

Talking about the heating and heat dissipation of LED

In recent years, #LED technology has been hailed as the next generation lighting technology, and with the increase of LED power supply, the cooling problem has attracted more and more attention. Researchers have long observed that the light drop or lifetime of an LED is directly related to its junction temperature, so if the heat is not smooth, the temperature is high and the lifetime is short.

Unlike the incandescent and fluorescent lamps of the past, the energy loss is large, but most of the energy is emitted directly through infrared light, and the heat source of the light source is very low. LEDs convert all energy (except energy consumed by visible light) into heat. Electronic products have gradually become the exception of high-density, high-density, and Led products. Solving the problem of Led heat dissipation has become the main problem of today's Led performance improvement and Led industry development.

#LED heating reasons:

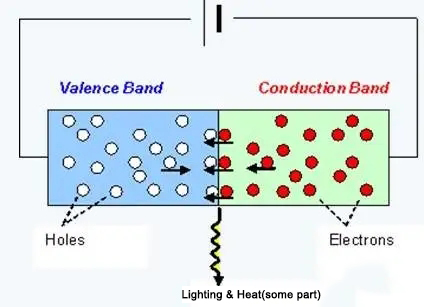

The reason why the LED heats up is that none of the added electricity is converted into light energy, and part of it is converted into heat energy. The indicator light is only 100lm/W, and the electro-optical conversion efficiency is about 20% to 30%. That is, about 70% of the electricity is converted into heat.

In particular, the occurrence of LED joint temperature is caused by two factors:

1. The internal efficiency of the two is not high. That is, when electrons combine with holes, photons cannot be 100% generated, usually due to "current leakage" which reduces the carrier recombination rate in the PN region. The leakage current multiplied by the voltage is the power in this part. That is, it converts to heat, but this part does not take up the main components, since the efficiency of the internal photons is already close to 90%.

2. None of the photons generated inside can shoot outside the chip, and part of the main reason why this is called external quantum efficiency is only about 30%, and most of it is converted to heat.

As mentioned above, the light efficiency of incandescent lamps is very low, but only about 15lm/W, but almost all the electricity is converted into light energy and emitted. The radiation is mostly infrared, so the efficiency of the light is very low, but the heat dissipation problem is eliminated.

LED cooling solutions:

The heat dissipation of Led mainly starts from two aspects.

The heat dissipation of the Led chip before and after the package and the heat dissipation of the Led lamp. Led chip heat dissipation is mainly related to the substrate and circuit selection process, because any LED can make a lamp, so the heat generated by the LED chip is eventually dispersed into the air through the lamp housing. If the heat is not well dissipated, the heat capacity of the LED chip will be very small, so if some heat is accumulated, the connection temperature of the chip will increase rapidly, and if it works at high temperature for a long time, the lifespan will be shortened rapidly. But that heat has to go through multiple paths before the chip can actually get to the outside air. In particular, the LED chips generate heat from the metal heat block, which generates heat from the solder to the PCB on the aluminum substrate, through the thermally conductive adhesive to the aluminum heat sink. Therefore, LED lighting includes both thermal diffusion and thermal diffusion. How the LED housing is cooled depends on the size of the power supply and where it is used. There are mainly the following cooling methods:

Aluminum Hot Pins: The most common thermal method, using aluminum hot pins as part of the enclosure to increase the cooling area.

Thermally conductive plastic shell: The plastic shell is filled with thermally conductive material during injection molding to improve the thermal conductivity and heat dissipation capacity of the plastic shell.

Aerofluidics: Making convective air out of a barnacle shape is the cheapest way to dissipate heat.

Fan: Inside the lamp housing is a high-efficiency fan with a long service life, which can enhance cooling, low cost and good effect. But changing the fan is cumbersome and not suitable for outdoor use. This design is relatively rare.

Heat Exchanger: Use heat exchanger technology to induce heat from the LED die to the chassis thermal pins. Large-scale lighting such as street lamps is a typical design.

The overall luminous efficiency of the LED is low, so the joint temperature is high and the life is shortened. In order to prolong the life and reduce the temperature of the joint, it is necessary to pay attention to the problem of heat dissipation.

Relevant technical support, R&D and manufacturing originate from Theluxchina, please log in to see more knowledge.

中文版

中文版